Modeling

Packed with extensive class libraries, functional building blocks, powerful tools and an efficient architecture, Plant Simulation is the ideal development environment for modeling your production systems and logistics processes.

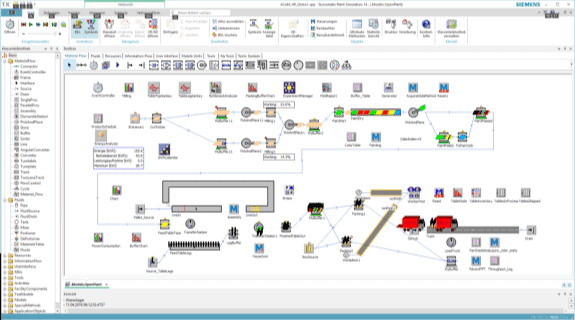

Object Orientation

The organisation of Plant Simualtion is fully object orientated. It supports hierarchical structures and inheritances to allow efficient implementations of complex models. Creating digital models is more intuitive through the use of objects. Thanks to hierarchical structures, you are able to keep complex models clear and concise while modeling in a top-down or bottom-up approach.

Objects & Class Libraries

Create, copy or derive new objects easily and without errors. Specify the inheritance of attributes and methods for faster and clearer parameterizations. Use objects from the included class libraries or build and manage your own libraries.

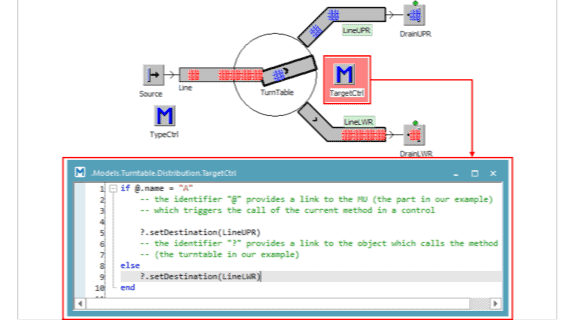

Interpreter & IDE

With the integrated development environment you can program and debug material flow control methods in Plant Simulation. Debugging at runtime using interpreter Technology: The generated code of the model is executed at runtime, therefore a compilation is not required.

Data-Driven Modeling

The architecture of Plant Simulation does not require a rigid methodology for designing and creating models. In data-driven modeling all the model’s details about processes, facilities, or resources are generated dynamically at runtime using up-to-date information from an external source (ERP or ODBC).

Classes & Objects

The following extensive class libraries are available out-of-the-box:

- Frames

- Material flow blocks – process block, store, buffer, line, pick and place roboter, …

- Resources – workplace, worker, shift calender, services, …

- Moving units – entities, transporter, container, …

- Fluids – pipe, tank, mixer, portioner, …

- User interfaces – dialog, chart, button, …

- Information flow blocks – method, table, variables, interfaces, …

- Extended libraries – crane, high bay warehouse, monorail, kanban blocks

SimTalk 2.0

With the programming language SimTalk you are able to modify the basic behavior of building blocks. Develop simple control structures such as conditions or loops and extend the functionality of classes and objects through methods. The new and simplified syntax provides extended functionality for an unlimitted modeling experience:

- Data types and operators

- Global and local variables

- Control structures (if … else, switch … case, for, while, …)

- Arguments and return values

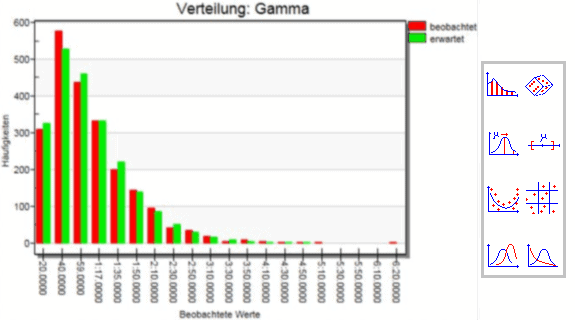

Statistic Tools

Statistical tools support you in data preparation, model creation and evaluation of simulation results.

For example, you can use the Datafit tool to parameterize statistical distributions for random values, such as failure times, setup and processing times, interim arrival times, and the number of rejects.

The statistic tools fields of application at a glance:

- Determine probability distributions

- Determination of confidence intervals

- Run regression analysis

- Find the parameters of truncated distributions

- Run Analysis of variance (ANOVA).

- Run independence tests

- Compare density functions of distributions